Two months back, a vehicle from tomorrow left a Los Angeles factory and hit the road.

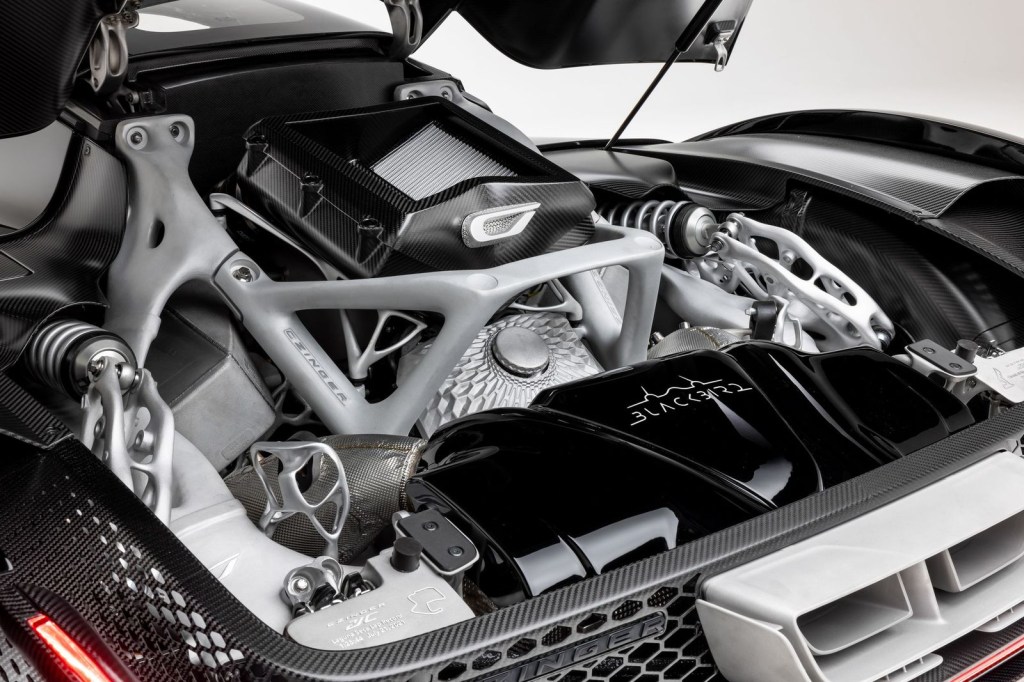

Called the Czinger 21C, it is mostly made with a gigantic 3-D printer. However, this hybrid hypercar is anything but a toy.

The two-seater rocket-like car, featuring one seat behind the other, comes with an initial cost of $2 million. It can reach a maximum speed of 253 miles per hour and accelerates from zero to 60 miles per hour in just 1.9 seconds.

“Right now, it’s the

fastest hypercar

In this world,” Lukas Czinger, the COO of Divergent—the company behind the production of the Czinger—told The Post. “It is completely street-legal.

As impressive as this vehicle might be, it serves as a blueprint for an entirely new approach to production. Similar to how a computer can transmit data to printers globally to create physical copies of documents, Divergent has the capability to send part specifications digitally to construct cars worldwide.

Moreover, this technology wouldn’t be restricted just to cars. Could it potentially be employed to erect something like a house?” “Absolutely,” replied Czinger, who is based in Los Angeles and is 31 years old. “We have the capability to virtually create any metallic construction.”

Divergent says it will completely transform the way in which cars and other items are produced.

STAY CURRENT WITH RECENT DEVELOPMENTS BY JOINING THE MORNING REPORT NEWSLETTER.

“We’re

tearing down the supply chain

” explained Czinger (with the ‘c’ being silent, hence pronounced like ‘Zinger’). “This printer is responsible for manufacturing the final product, which means there’s no need to be concerned about a supply chain.”

However, it comes with a hefty price tag. The research and development for the printer cost $500 million before anything tangible was made. “Raising funds wasn’t simple,” confessed Czinger. “This was an investment-heavy process but the core concept revolves around establishing a novel type of manufacturing.”

With a weight of approximately two tons and dimensions similar to two shipping containers placed atop one another, this printer utilizes metallic powders along with lasers (that melt the powder) to construct components incrementally, layer by layer.

“A single part,” said Czinger, “could have 5,000 layers. One day, each printer will be its own factory. This is what we call digital manufacturing.”

Czinger thinks of it as “one factory that can make any product as opposed to one factory that makes only one product. We’ll have instant manufacturing, in which the printer can make a Ferrari rear frame for one of its automobiles and then, in the next second, it can print a cruise missile for Lockheed Martin.”

Divergent is the brainchild of Lukas and his father, Kevin Czinger. Kevin, from Ohio, founded the company in 2014 following careers in law and investment banking.

As things got off the ground, Lukas, who has an engineering degree from Yale University, “quit my banking job and rolled the dice, betting on Kevin, betting on myself, betting on the vision of Divergent.”

Currently, said Czinger, creating one of his company’s cars from design to the finished product takes about 1,000 hours. Done the old-fashioned way, “with a manual chassis [building] process,” he added, “you can probably add another 600 hours.”

Although Divergent is at the forefront of the new auto revolution – and road-worthy proof that it works – they are not the only ones changing the game.

In fact, changing batteries in electric cars, which lose charging power over time, is another growth area.

“There’s a player in China that allows for battery swapping,” Phillip Kampshoff, a McKinsey & Company senior partner who focuses on the automotive industry, told The Post.

At some stage, Tesla reportedly explored the idea of battery swapping as well but decided against pursuing it further.

Kampshoff added, “In the future, once newer generations of batteries emerge or improved versions become available, an upgrade will be feasible.” Currently though, such an upgrade cannot be done.

What might occur – and potentially take place once Divergent acquires additional 3D printers – is the immediate fabrication of rare automotive components. As Kampshoff explained, “Should you be a provider for a specific component,” production lines for those parts will eventually cease when manufacturing older model vehicles becomes unprofitable.

However, using a 3D printer along with a digital copy of each component’s design allows them to be manufactured immediately and, as Kampshoff stated, “avoid occupying storage space in a warehouse for a decade.”

Cars might get affordable enough that keeping an old vehicle becomes impractical. A potential solution heading toward this future could be the Slate, which has received funding from Amazon’s creator, Jeff Bezos, among others.

As reported by Slate, customers will have the opportunity to customize their cars according to their preferences—whether choosing between a pickup truck or an SUV—and can make adjustments post-purchase as well. The starting price for these vehicles is anticipated to be around $20,000.

Slate is thrilling because it introduces mass customization, which might seem paradoxical but isn’t,” said James Meigs, a senior fellow at the Manhattan Institute specializing in technology. “Should they deliver as promised, it will prove both pragmatic and functional without breaking the bank.

It may not require being among the wealthiest individuals globally to attempt establishing your very own automobile business.

I believe we’ll observe an increase in individuals investing in electric vehicle startups that cater to specific markets,” forecasted Meigs. “In China, small urban cars have emerged which excel at zipping around and fitting into compact areas.

“Thirty or 40 years ago, nobody in their right mind would have started a car company. But with the battery-operated vehicles, it’s a little easier today, and people are willing to try different things. Maybe we’ll see things we can’t even predict and don’t expect” – Kampshoff goes so far as to imagine self-driving campers that can function as mobile hotel rooms.

“I believe the future holds excitement,” Meigs noted.