Dutch start-up Eyeo has

secured €15 million

for initial financing to develop

new image sensor technology

The objective is to increase a sensor’s light sensitivity threefold. This advanced color-splitting photonic technology is claimed to “unlock image quality, color precision, resolution, and cost-effectiveness previously unattainable.”

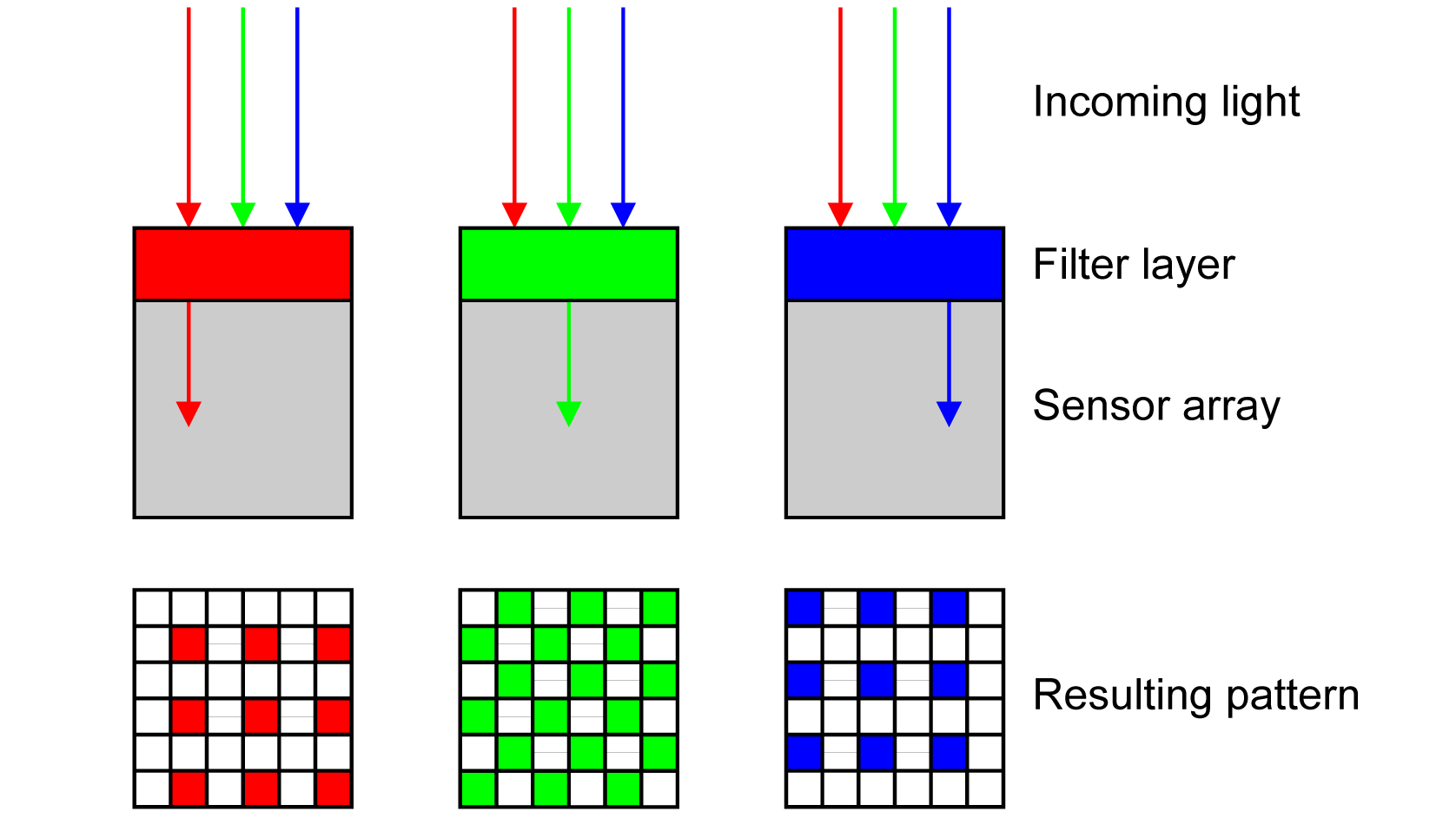

For many decades, color image sensors have nearly always employed a Bayer color filter array, splitting incoming light into red, green, and blue wavelengths that are subsequently detected by respective photodetectors on the sensor’s surface. Typically, these sensors were configured with half of the detectors capturing green light, one-quarter for red, and another quarter for blue (known as RGGB). However, various modifications to this setup have emerged over time.

Although Bayer filter technology is essential for enabling an image sensor to capture colors, it comes with certain limitations. The main trade-off is that every sensor pixel captures merely a portion of the incoming light because around half of it gets obstructed since it corresponds to incorrect color wavelengths. Consequently, this reduces the sensor’s dynamic range and increases susceptibility to producing noisy images under dim lighting. Additionally, the demosaicking algorithms employed to convert individual red, green, and blue color readings into complete color information tend to soften the resulting digital picture somewhat, thereby restricting the level of intricate details that can be discerned.

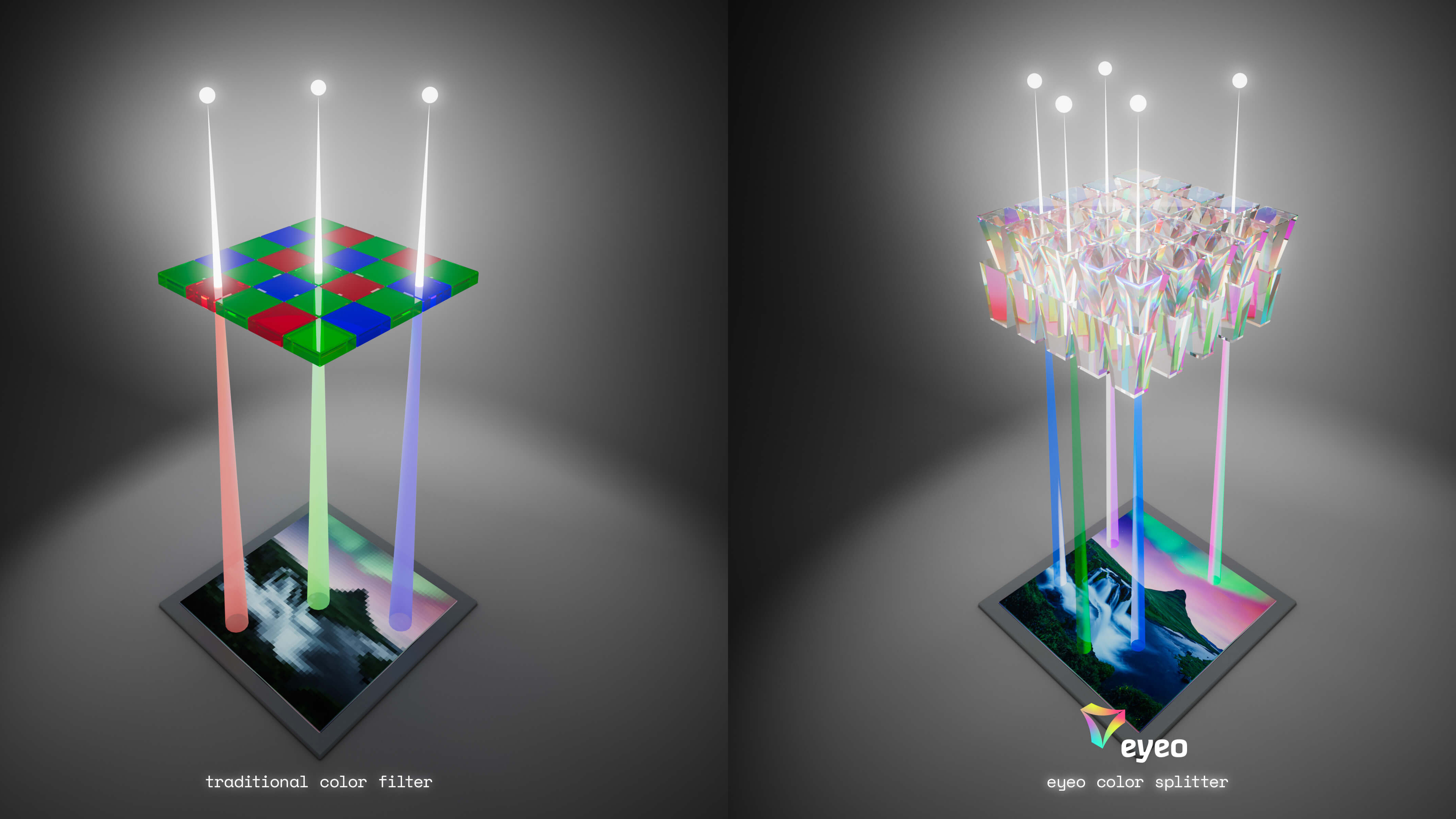

These constraints have been recognized for quite some time, prompting various efforts to tackle them. One well-known solution is the Foveon X3 sensor, now closely associated with Sigma, which employs an entirely distinct method of sensor design that eliminates the Bayer filter to significantly boost light passage. In contrast, Eyeo’s methodology aims at the same objective but relies on conventional CMOS sensors instead, modifying how light reaches the sensor pixels.

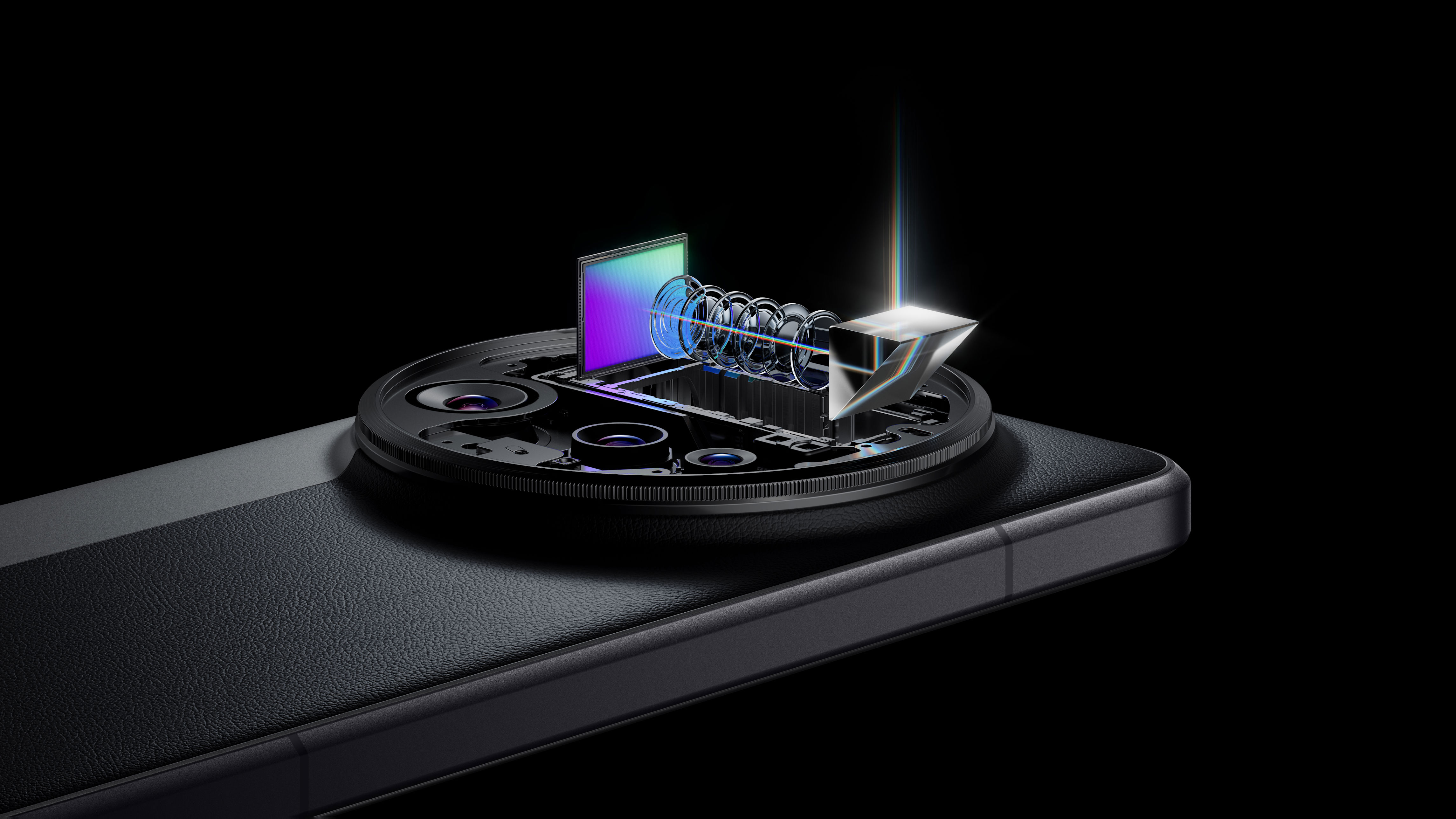

Instead of screening the incoming light (thus obstructing a significant portion of it), Eyeo’s technology

guides

Light enters the photosites through vertical waveguides, officially known as ‘wafer-level-integrated vertical-waveguide sub-diffraction-limited color splitters.’ This technology employs layered vertical waveguides to intercept full-spectrum white light and channel each color wavelength to distinct photosites. These waveguides are calibrated according to the typical sensitivities of human cone cells for color perception; however, they can also be adjusted for various spectra such as ultraviolet when needed. According to Eyeo, modifying just the color-separation layer allows the remainder of the CMOS sensor and its electronic components to stay unaltered. Additionally, the firm mentions having established collaborations with key players in image sensor manufacturing. They plan to utilize recent investment capital towards developing an item suitable for large-scale production.

By abandoning traditional color filter arrays, it’s possible to significantly boost light transmission, leading to markedly better image quality without enlarging the sensor physically. This could potentially enable shrinking camera sensors even further while keeping their output quality at an acceptable level, which would be particularly beneficial for compact gadgets such as smartphones and surveillance systems. Additionally, this innovation allows reducing sensor dimensions without compromising megapixels. Currently, using a Bayer filter restricts pixel size to a minimum of 0.5 microns because anything smaller may cause image deterioration from optical diffraction effects. By eliminating these filters and substituting them with vertical waveguides, sensor makers have the opportunity to decrease pixel sizes beyond present constraints. Regarding practical applications, Eyeo mentions that “evaluation kits should become accessible to certain clients over the coming two years.” Stay tuned!

Enjoying this article? To read more stories like this, follow us on MSN by tapping the +Follow button at the top of the page.